Hospital operations in Bradford are set to increase with input from Gilberts Blackpool contributing towards a new NHS surgical day case unit.

The roof-top plant necessary to operate the unit at St Lukes Hospital for Bradford Teaching Hospitals NHS Foundation Trust is being screened by over 500m2 of Gilberts weather louvres (WGK75).

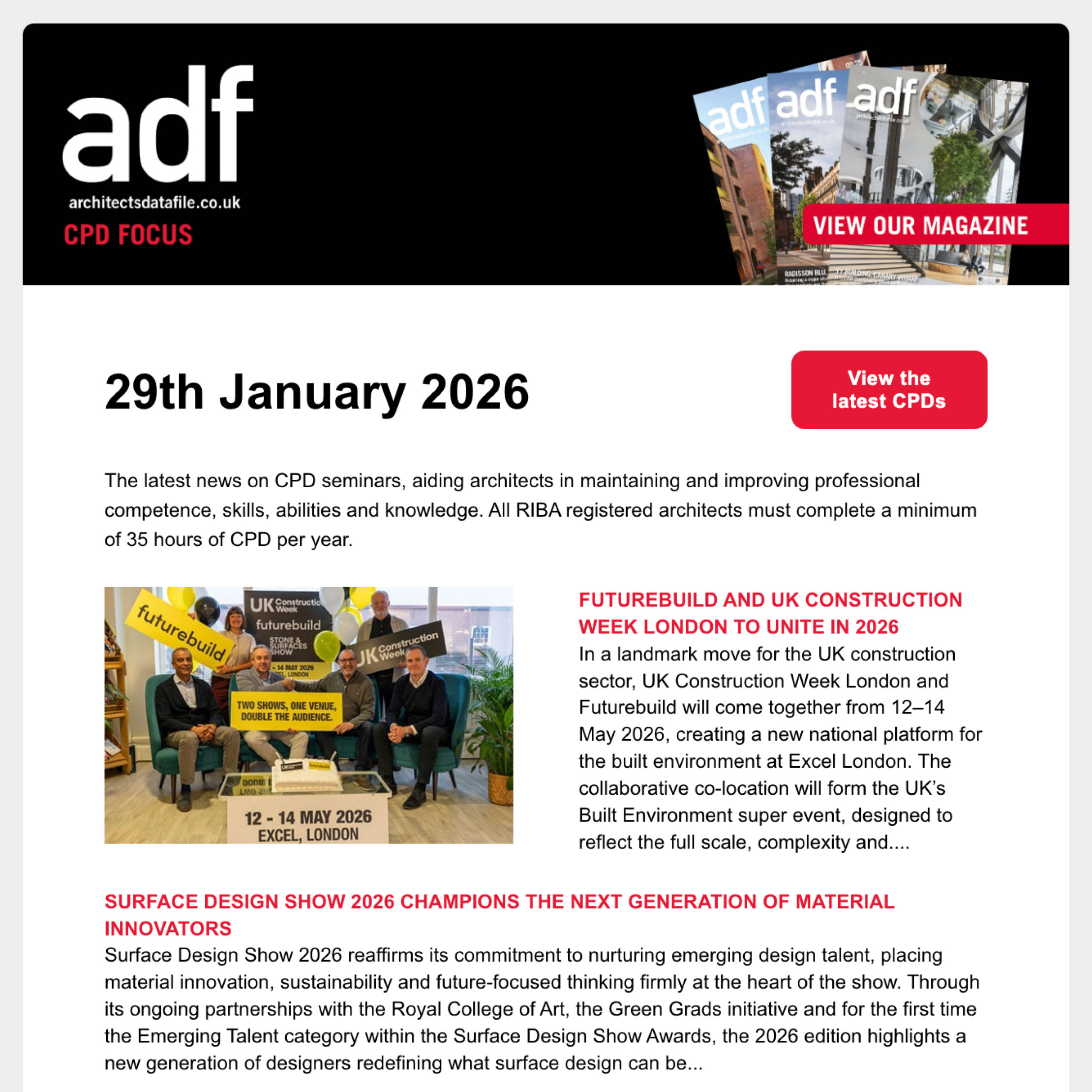

In a complex configuration, the core 102m long x 3.5m high screen, powder coated in matt signal black, runs the entire perimeter to provide an attractive ground-level aesthetic to visitors to the facility and a degree of protection from the elements for the plant behind.

An additional L-shaped 44m louvre within includes insulation, doors and a cat ladder to minimise sound from and allow maintenance access to the equipment needed to power the two-storey unit and its two operating theatres.

Gilberts designed and fabricated the louvre components in its state-of-the-art manufacturing facility before installing on-site for principal contractor Darwin Group. The screen is an integral part of the unit’s design which aims to improve the patient experience, including an interior laid out to provide a circular patient pathway and a generous landscape buffer.

Gilberts’ approach, integrated with Darwin Group’s offsite modular construction method, has delivered the project up to 60 per cent faster and with up to 90 per cent less waste than traditional building methods.

Alastair Pryce, head of project delivery at Darwin Group, said “Gilberts has proven to deliver the reliability, quality and service that Darwin Group has built its reputation on, as a leader in offsite modular construction methods- to the extent that we asked them to also provide a small louvre for integration into the façade cladding.”

Once operational, the new unit will undertake high volume, low complexity surgery which will increase the Trust’s operation capacity by more than 5000 a year.

Founded 60 years ago, and still family-owned, Gilberts is the UK’s leading independent air movement engineer. It offers a comprehensive range of factory- and site-assembled louvres for screening, weather and noise protection: its acoustic louvres are BSRIA (Building Services Research and Information Association) validated.

Gilberts is unique in its ability to design, manufacture and test all products- including bespoke fabrications- in-house, to the extent it even designs and manufactures its own tools at its 140,000 sq ft head office and production facility.